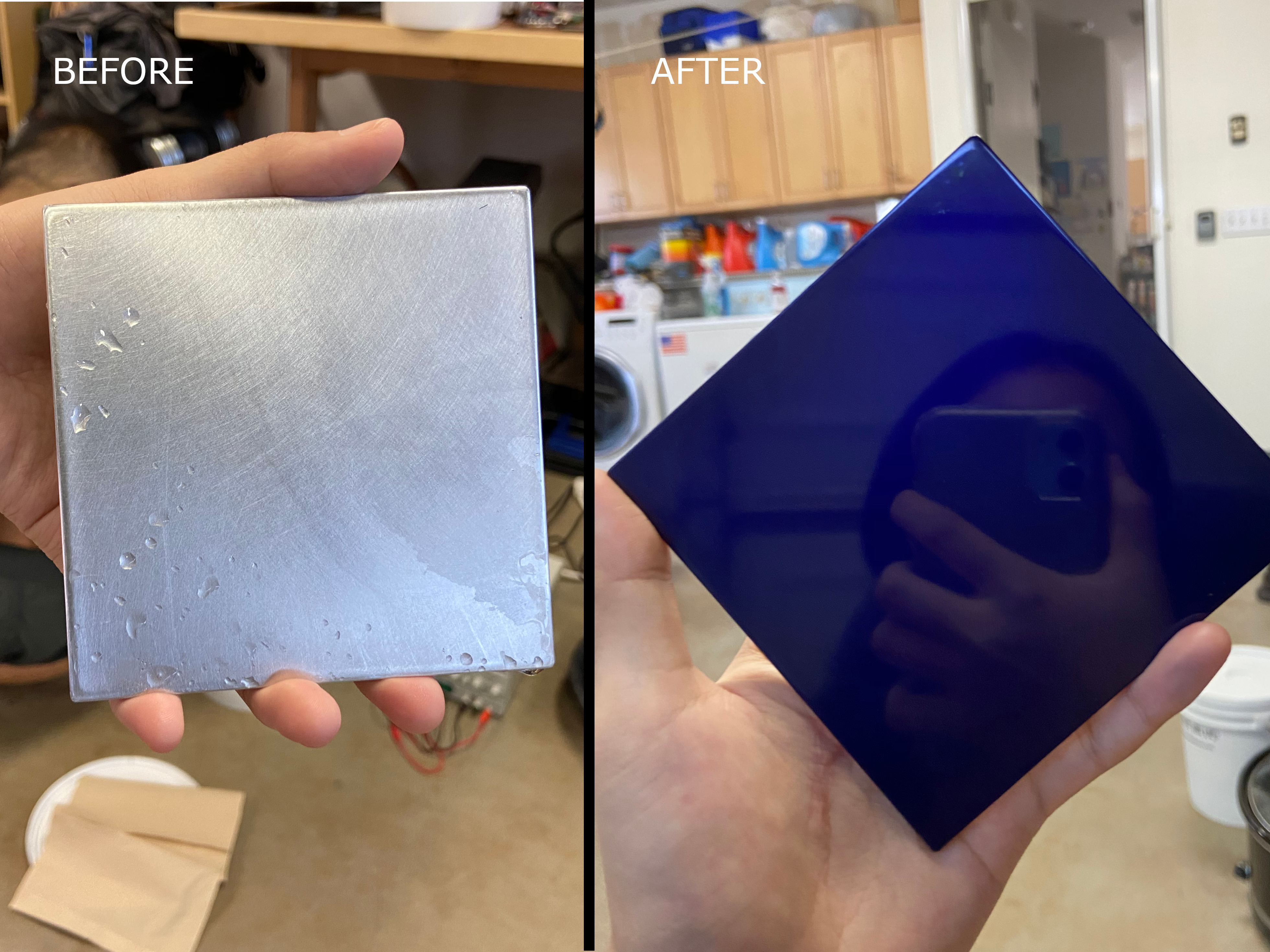

Anodizing Aluminum

During the COVID-19 lockdowns, I was tasked in an electronics class to do any at-home project that dealt with electronics. Because I did not have an electronics kit yet (arduinos, breadboards, LEDs, etc.), my dad proposed that I anodize an aluminum square. Anodizing is an electrochemical process of creating a durable aluminum oxide layer on the surface of a metal part by submerging it into an electrolytic bath. This layer is porous and accepts dyes well, so it's also used to color metals.

For the project, I went through the entire anodizing process, creating the electrolytic bath with a 1:1 mixture of sulfuric acid and distilled water, setting up the power supply, anode and cathode so that current would be passed through the mixture, suspending the piece of aluminum in the mixture, eventually dyeing it blue and sealing it. That's a brief overview of the steps, but it was extremely time-consuming. The process itself was not challenging because my dad was there to instruct me each step of the way, but initially understanding the science behind it was a bit difficult.

With this project, I learned how to anodize aluminum. I also learned how to use a power supply and expanded my understanding of electronics and its applications. I believe that the most important takeaway was the safety aspect---I was working with a lot of things that were dangerous to breathe in or touch with bare skin, so there was no room for being careless or making stupid mistakes. It tested my ability to follow directions precisely.